The shock absorber is an important component of the automobile suspension system. It can buffer the vibration of the vehicle, and at the same time it can effectively prevent rebound and improve the smoothness and stability of the vehicle. The shock absorber is also called a damper. It is an important buffer component. Technically speaking, it is a hydraulic pump that can absorb the kinetic energy of the suspension system and dissipate the kinetic energy into the atmosphere in the form of heat. Now the mainstream shock absorbers can be divided into strut shock absorbers and telescopic shock absorbers. Their structures are different, but the principles are exactly the same.

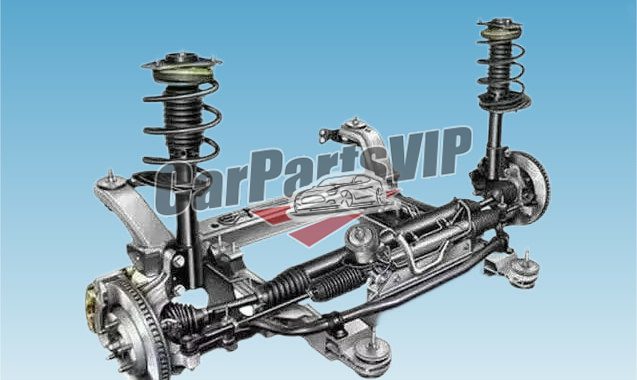

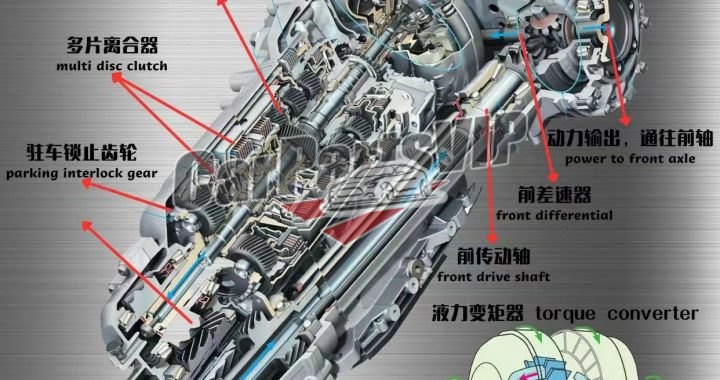

Take the strut shock absorber as an example to understand the working principle of the shock absorber: the top of the strut shock absorber is connected to the body, and its bottom is connected to the steering knuckle. The steering knuckle is connected to the lower arm, and the lower arm is connected to the subframe. This connection method allows the shock absorber to move only in the vertical direction, which is also the best way to achieve the shock absorption effect. Because the steering knuckle can rotate, the wheel can rotate within the limited rotation angle of the steering knuckle. The main components of the strut shock absorber are shock absorber, coil spring, top strut mounting seat, dust cover above the piston rod, and oil seal. The internal structure of the shock absorber includes a piston rod, a rebound block, a piston, a base, and hydraulic oil. There are two cylinders inside the shock absorber, a working cylinder and an oil storage cylinder. The working cylinder is always filled with hydraulic oil, and there is also some hydraulic oil in the oil storage cylinder. When working, the compression valve on the base will control the flow of hydraulic oil between the two cylinders. This shock absorber designed with two cylinders is called a double-cylinder shock absorber. In order for the shock absorber to perform at its best, no gas can enter the working cylinder, and it must be ensured that there is always hydraulic oil filling. At this time, the oil storage cylinder comes into play. The oil storage cylinder stores enough hydraulic oil. When the piston moves down, the excess hydraulic oil will be squeezed into the oil storage cylinder due to the pressure. When the piston moves upward, the volume of the working cylinder increases, and the hydraulic oil in the oil storage cylinder will be pulled back. In this way, the working cylinder is always filled with hydraulic oil. In this process, the oil storage cylinder is only half-filled, and the rest of the space is filled with nitrogen or liquid nitrogen that can be compressed and expanded. Since nitrogen has the characteristics of compression and expansion, it is just right to use it to fill.

The linkage details of the shock absorber when working, first of all, is the downward pressure process. When the external force presses down, the piston moves downward. At this time, the compression valve in the piston opens, and the hydraulic oil flows into the upper chamber through the valve. Because the valve is small, the hydraulic oil will be throttled, and the speed of upward flow will slow down. When the piston continues to press down, the oil pressure in the lower chamber begins to increase. When the pressure is greater than the bearing value of the base compression valve, the compression valve on the base will automatically open, and the hydraulic oil will flow to the oil storage cylinder. In this process, each valve throttles the hydraulic oil, forming a damping of the downward pressure. Simply put, it is the throttling speed limit of the valve, which realizes shock absorption and buffering. Next is the rebound process. When the rebound begins, the pressure in the lower chamber slowly recovers, and the compression valve on the base automatically closes. When the piston moves up, the volume of the lower chamber increases, the oil pressure begins to decrease, and the rebound valve on the base automatically opens. The hydraulic oil in the oil storage cylinder is pulled back. At the same time, the hydraulic oil in the upper chamber will flow into the lower chamber synchronously. This process will also be controlled by throttling and form a damping force. Since both the downward pressure and the rebound process are affected by the damping force, the two functions of shock absorption and rebound prevention are realized. This is the working principle of the automobile shock absorber.