1、Wheel Speed Sensors

There are four wheel speed sensors, one on each wheel. They measure how fast each wheel is turning and help the system detect if a wheel is slipping or locking up.

2、Yaw Rate Sensor

This sensor measures how much the car is rotating around its vertical axis — in simple terms, it tells whether the car is skidding or swinging sideways. It’s a very sensitive sensor that can detect even tiny movements of the car’s body while driving.

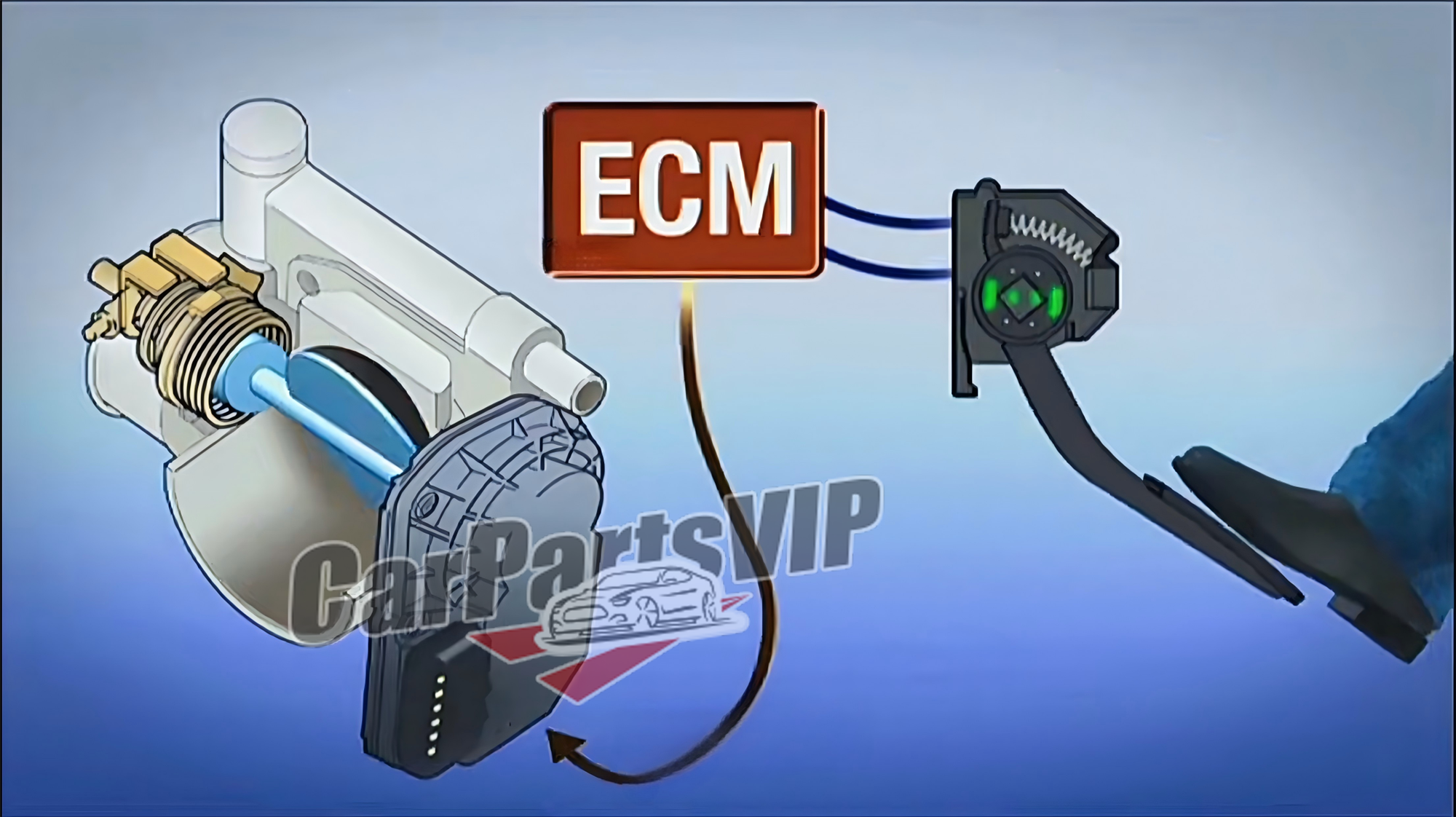

3、Steering Angle Sensor

This sensor tracks how much the driver turns the steering wheel. It helps the system understand the driver’s steering intention and compare it with how the car is actually moving.

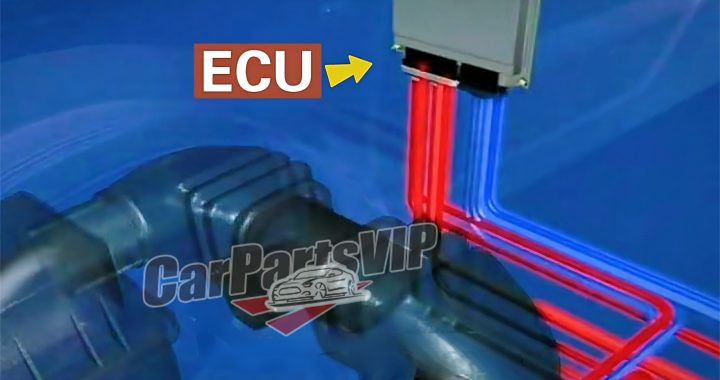

4、ESP Control Unit (ECU)

The control unit is the “brain” of the ESP system. It collects data from all the sensors, analyzes the car’s driving condition, and decides when to step in. If it detects a possible loss of control, it sends signals to adjust the brakes or engine power to keep the car stable.

5、Hydraulic Modulator

This part controls the brake pressure in the braking system. It can apply different braking forces to each wheel individually, helping the car stay balanced and stable when turning or driving on slippery roads.

Working Principle of the ESP (Electronic Stability Program) System

When the vehicle encounters a fallen obstacle ahead and the driver makes an emergency left steering maneuver to avoid it, the steering angle sensor detects the driver’s steering intention and transmits this information to the ESP electronic control unit (ECU).

However, due to the vehicle’s speed and inertia, the vehicle body still tends to move straight toward the obstacle. Since the front wheels are already executing a left-turn operation, the rear of the vehicle will inevitably swing out to the right.

At this moment, the yaw rate sensor detects the vehicle’s tail-swing signal and sends it to the control unit, which immediately applies braking force to the left rear wheel. This generates a counteracting force that suppresses the rear-end swing and helps the vehicle maintain its intended direction of travel.

Next comes the counter-steering phase. After completing the initial left-turn maneuver, the driver typically straightens the steering wheel or even turns slightly to the right. Due to this oversteering, the rear of the vehicle now tends to swing out to the left. To counteract this yaw moment, the ESP system applies braking force to the left front wheel, creating an opposing torque that stabilizes the vehicle and reduces the tail-swing effect.

Through these coordinated and timely interventions, the ESP system assists the vehicle in returning to the driver’s intended driving trajectory, maintaining stability, and safely avoiding danger.

This describes the working principle and interaction mechanism of the components that make up the ESP vehicle stability control system.

Reminder:

The ESP system is an electronic driver-assistance system. While it can significantly improve vehicle stability and help prevent skidding or loss of control in emergency situations, it does not guarantee 100% effectiveness. Under extreme driving conditions, there is still a risk of losing control.

In addition, not all vehicles use the name “ESP” (Electronic Stability Program) for this system. Different manufacturers may use different names, such as VSC (Vehicle Stability Control), ESC (Electronic Stability Control), or DSC (Dynamic Stability Control).

In order to solve this problem, a rack-and-pinion steering design was developed. A bevel gear, also called a helical gear or steering gear, was added to the end of the steering column. This gear meshes with a rack, which is connected to the front wheel through a steering rod. When the steering wheel is turned, the steering gear drives the rack to move left and right, which drives the rod to push and pull the front wheel to achieve a turn. Due to the addition of racks and pinions in this design, the steering transmission ratio becomes smaller. According to the requirements of the national standard, this ratio is between 12:1 and 24:1. Therefore, for a family car, when the wheel is returned to the correct position, the steering wheel needs to be turned one and a half turns before it can be stopped. In other words, the steering wheel needs to be turned three times from the extreme left to the extreme right. Now you should know why the steering wheel is designed to be round.

In order to solve this problem, a rack-and-pinion steering design was developed. A bevel gear, also called a helical gear or steering gear, was added to the end of the steering column. This gear meshes with a rack, which is connected to the front wheel through a steering rod. When the steering wheel is turned, the steering gear drives the rack to move left and right, which drives the rod to push and pull the front wheel to achieve a turn. Due to the addition of racks and pinions in this design, the steering transmission ratio becomes smaller. According to the requirements of the national standard, this ratio is between 12:1 and 24:1. Therefore, for a family car, when the wheel is returned to the correct position, the steering wheel needs to be turned one and a half turns before it can be stopped. In other words, the steering wheel needs to be turned three times from the extreme left to the extreme right. Now you should know why the steering wheel is designed to be round.